FR Range – 850kW to 13000KW

Pyrovent (type FR) – 850 to 13,000 kW

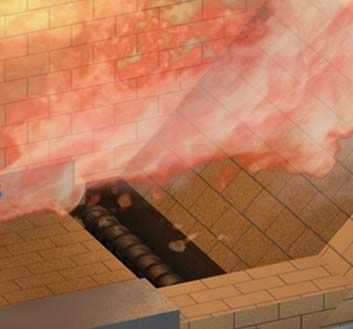

Direct firing system with high-temperature fluidised bed combustion to maximise the energy yield of wood residues from wood processing

The very dry and dust-like fuel is blown through one or more feed pipes into the fully ceramic-lined, highly insulated combustion chamber. The blowing action combined with the specially-developed combustion chamber geometry ensures optimal burnout of the fuel and the required turbulence and flow characteristics.

The heat storage in the fireclay mass ensures correspondingly high efficiency combustion chamber temperatures, which guarantee low emissions. The horizontal three-pass flame tube/smoke tube boiler is mounted on top of the combustion chamber to serve as a hot water boiler up to 110 ºC or above 110 ºC. If required, steam boilers or thermal oil boilers can also be supplied.

Main Features

- Three-pass boiler (6 bar – higher pressure levels on request)

- Safety heat exchanger (integrated in boiler)

- Combustion chamber

- Blow-in connector

- Secondary air supply

- Flue gas recirculation supply

- Automatic ash removal by water-cooled screw conveyor (optional)

- Combustion chamber door

- Pneumatic boiler cleaning (optional)

Benefits & Advantage

- Three-pass flame tube boiler or two-pass boiler with water wall with flue gas temperatures below 190 °C at full load

- Output: 850 to 13,000 kW

- Integral backup heat exchanger to maintain quick controllability to DIN 4751 part 2

- Modulating load control from 60 to 100 % depending on system type and fuel

- Injector principle for fuel charging, hence no wear to blower fan

- Low ash removal requirement in combustion chamber thanks to fluidised bed combustion

- Optional staged combustion (low NOX principle)